Tesla's Supply Chain Impact Revealed - BIG Supply Chain Lessons 🔋

Impact Report 2023 Breakdown

Tesla Inc., an American electric vehicle and clean energy company, has revolutionised the automotive industry with its innovative manufacturing and supply chain management approach.

We should probably add AI and Robotics company here for safe measures.

So, I will jump headfirst into Tesla's supply chain operations, the lessons procurement and supply chain professionals can learn from Tesla, the disadvantages of its approach, and how other companies can adopt similar strategies.

Caveat - I own a Tesla Model 3, and I love it. I'm also deeply concerned by Elon's right-wing comments and engagement on the horrible racism being displayed by a small percentage of the UK population at the moment.

Introduction

Tesla's mission is to accelerate the world's transition to sustainable energy. A noble mission for sure. Central to this mission is a supply chain designed to ensure efficiency, sustainability, and resilience.

Without this, this endeavour is doomed to failure.

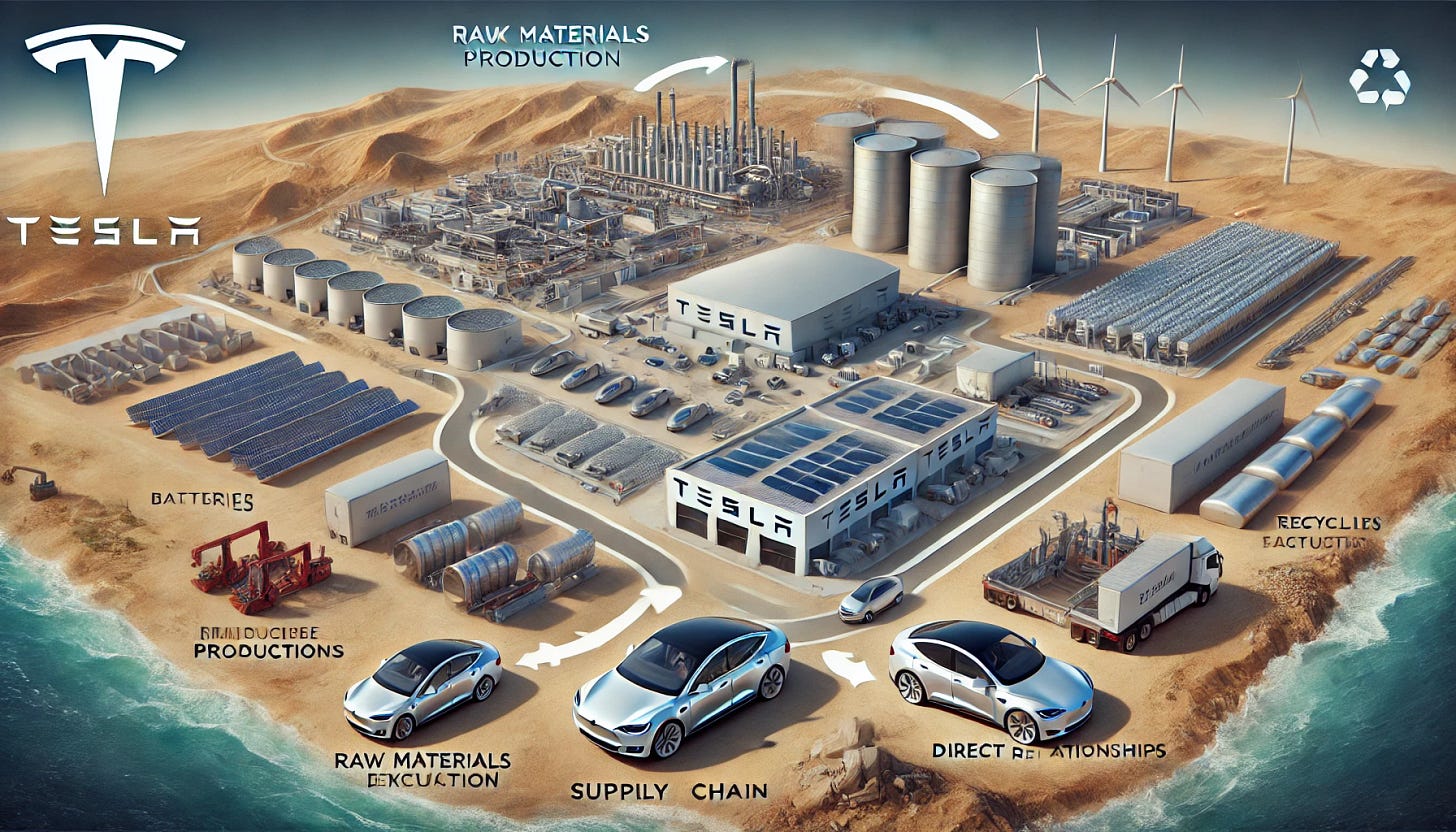

Tesla's supply chain strategy is characterised by vertical integration, responsible sourcing, advanced recycling programs, and an unwavering commitment to decarbonisation.

Central to this mission is Elon Musk's vision of constant innovation. For instance, Tesla developed the world's most giant casting machine for the Model Y, significantly reducing the number of parts and simplifying production. This focus on innovation streamlines manufacturing processes and enhances the overall sustainability of Tesla's operations.

Tesla's Supply Chain Operations

Vertical Integration

Tesla's supply chain is notable for its high degree of vertical integration. Unlike traditional automakers, Tesla manufactures many components in-house, including batteries, motors, and software. This approach allows Tesla to control quality, cost, and innovation. It returns to earlier manufacturing models, like Henry Ford's approach.

Tesla's approach opposed most modern supply chain operations: "The vertical integration model is widely derided today. Modern supply chain managers pride themselves on outsourcing as much as possible and confining their direct processes to what are called core competencies"—Sold Out.

In-house Manufacturing:

Battery Production: Tesla's Gigafactories, located in Nevada, Shanghai, and Berlin, are pivotal to its strategy. These facilities produce batteries at scale, ensuring a reliable supply of one of the most critical components of electric vehicles.

Keep reading with a 7-day free trial

Subscribe to The AI Procurement Blueprint to keep reading this post and get 7 days of free access to the full post archives.