I saved a business £6m and it meant nothing

Here's a story about what I learned matters when big savings are secured

I saved one business £760k. That’s what’s on my CV - at least it was when CVs were still a thing.

Or it might have been £6m in reality.

More on that in a moment.

This was a big saving and the original £760k saving was a conservative estimate. It looked like we might need to pay a supplier £4m for their wares. My calculations, based on the data, the specifications, and the amount of work they’d need to do to get them right for us, pushed it closer to £7m.

But I worked from the existing quote.

Turned out their new quote was closer to 9m so I could claim this to be a £6m saving…

Hence the title.

But here is the truth of it - it meant nothing.

Yes, I can hear you saying that it does.

That Procurement is there to save the business money. And I agree. I used to be super proud of this. But on reflection, what led to this saving was nothing short of a hard six months of outright internal warfare, in a kinda loving way, in a kinda - if you screw this up you’re out kind of way.

And that was stressful as a 27-year-old who was blagging his way through consultancy, leaning on knowledge of commercials and contracts to supercharge my sourcing knowledge. Then add an unexpected opportunity to do this and lead on the wider supply chain piece. I was over my head, with my second child on the way.

Why am I telling you all of this - because context matters.

And now I’m going to tell you why the saving means nothing - with the rough of it first.

I don’t know if they took that saving opportunity

I’m not going to name the suppliers I talk about here. No one was doing anything bad. But the programme I joined wasn’t in good shape.

I joined at the end of the bidding stage into a big procurement that another big supplier was undertaking to help it deliver a project to the UK government. This contract was valued at around £65m.

As part of our bid, we had a 1-3-year-old list of suppliers and quotes (at least that’s what they told me).

When I got in, half the quotes were missing, the data was beyond useless, and the current specification of what we needed to deliver had moved on, and no one had reassessed the suppliers who would deliver components and parts that no one on our tiny ball of rock in this vast galaxy was making.

Already - we’re in a bad place.

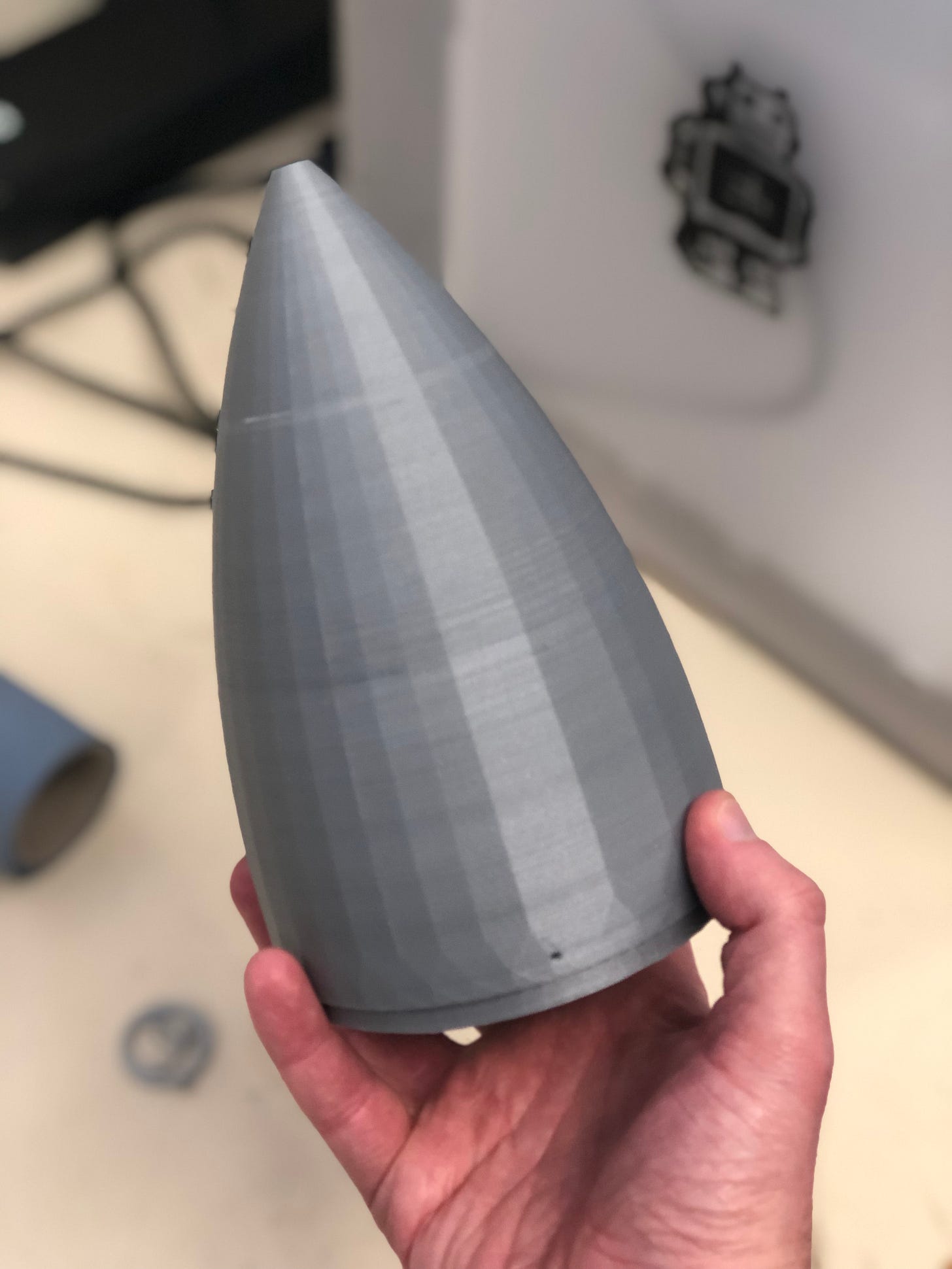

But one of these suppliers could not deliver to the specification. The engineers, who I spent 3 months befriending, taking a genuine interest in what they do, chatting, chilling, 3D Printing (I’m now an avid 3D printer nerd myself) told me as we ate lunch and downed gallons of tea. We’re English - we like tea (even the Greek guy).

But they were concerned as the programme team, which I was a member of, were busy locking in a deal with that supplier who couldn’t meet the specification.

I spent days going through 200 lines of complex technical specifications, cross referencing it with the current preferred supplier, looked over the sizing issue - I mean, one of their parts wouldn’t even fit inside what we were building, and I took a leap of faith. The programme team were effective paying me to lead on the Supply Chain, Procurement and Contracts side. And I was about to pull them all into a room and tell them that we had to stop everything we were doing with that supplier, go back out to market with an RFP, we would include this supplier and five others, and we would see if we could find someone who could meet out specs.

And I had spent the last three weeks on the phone with suppliers in Europe, the UK, and the US getting others interested in this project.

The Programme Team knew there was a potential issue - I mean the Chief Engineer was on this, and he had noted it but hadn’t pushed it, which pissed off his engineers. It took the one person who was a consultant, not an employee, to push a massive change, that could impact the schedule, to push this.

Call it the naivety of youth.

I call this risk management.

Because I know that if we were to go with the existing preferred supplier, we should drop our tools and walk away.

But everyone agreed and gave me the space to work it through.

In the end, we found a company on the outskirts of London, in a shabby industrial estate who could do it. They couldn’t ruggedise them, though - we’d need to give that to another supplier, but we had quotes from them. All in all, this secured a £760k saving against the original quote but £6m on the new quote.

The contract terms were superior and better for everyone involved.

They gave us a free unit worth £30k at retail to play with before we even talked about contract terms. They didn’t even care if we blew it up.

And that’s where the story ended for me. I decided I wanted to take a few months off over the summer before Baby number 2 arrived, and we were gearing up to move into our current house. Life was stressful - see context matters.

So I set everything up, we just needed signatures, but I still don’t know if they signed. I think they probably did, but I wanted detachment. The long days that rolled into months had drained me and I didn’t want to know anything else about it once I left.

But the savings matter less than what I learned.

I learned that Procurement teams can make a huge impact and become the best of partners with engineers and those “nerdy” folk.

I learned that the Commercial and Financial teams would back a data-led decision with clear objectives, projected outcomes, and savings.

I learned that a good presentation, and I don’t mean slides, can change the tide.

I learned that drinking tea and genuinely being interested in what my colleagues did and what they were passionate about made us an incredible team that was hard to stop.

I learned that suppliers are everything. That some out there will do all they can to help you if you show a willingness to help them or even be interested in what they do.

As I walked on the workshop floors, picked up parts I didn’t understand, and did everything I could to learn about physics, thermodynamics, electrical units, software and more, I realised that being a good Procurement person meant being a decent, good, and curious person.

And that’s what you need to do in every role - to get the promotions and opportunities and take control of your career.

Without the right part in right place at the right time, savings don't matter... Good story.

Great article. Drinking tea and bring interested and curious in everything is my key takeaway